Offshore Safety – Saipem designs and implements the OIE

saipem.com

Article by Francesco Valentini

The trial of British Petroleum (BP), the British company responsible for the 2010 environmental disaster in the Gulf of Mexico, was concluded on 4 April 2016 in New Orleans.

The final judgment has certified a plea-bargained for a tune of about 20 billion dollars that the company will be forced to cover for the ecological damage caused by the oil spill which followed the explosion of the Deepwater Horizon platform.

To solve the problem of the oil spill, the most important offshore oil spill that has ever occurred, several ways have been tried: firstly with some types of ROV (remote operative vehicle) in order to close the valve located on the sea floor, and later with the operation called “Top Kill”, it was attempted to close the main well injecting cement from some auxiliary wells. The environmental damage both to the animal and plant species affected and to the economy for the coast reached by the huge oil slick were incalculable.

The question that industry experts have asked themselves is: how can we use the new offshore technologies to contain the tragic effects of large blowouts?

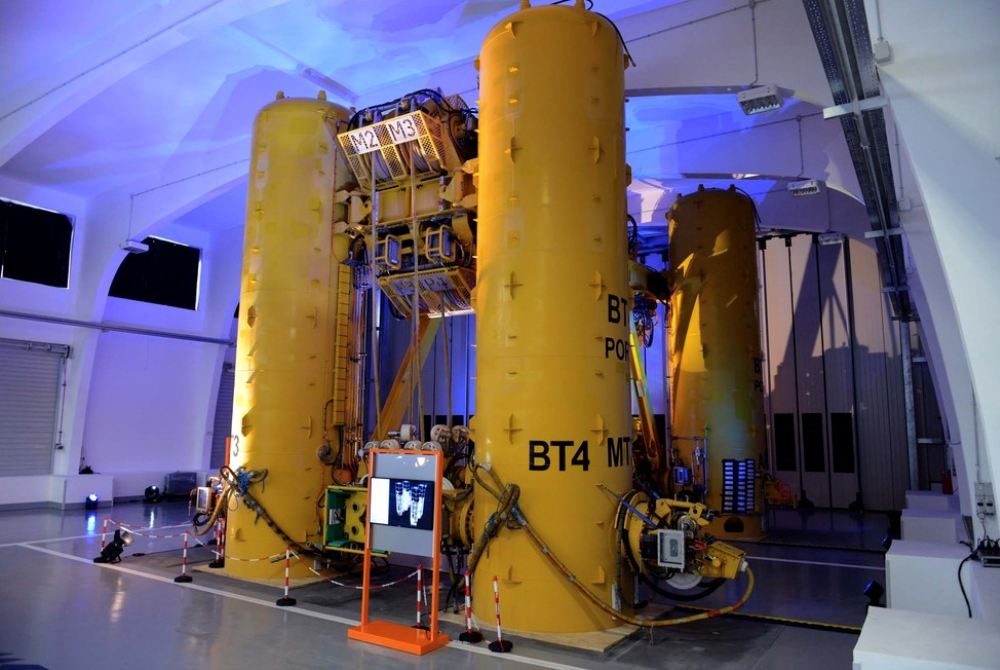

The answer comes from Italy, is called Offset Installation Equipment (Oie), and was set up in the final part of Warehouse 23 of the port of Trieste, commissioned by Osrl (Oil Spill Response srl) to Saipem that realized it togheter with two companies in the Northeast, the Cartubi of Trieste and the Depretto of Schio.

As a matter of fact, Saipem in the Upper Adriatic has recently successfully tested the OIE system. OIE permits to install the “capping stack” and the relative auxiliary equipment remaining at a safe distance from the point of intervention. With a range of 500 meters the system can be used in waters of depth ranging from 75 to 600 meters, while managing it through the use of common ROV.

“A UNIQUE SYSTEM IN THE WORLD”

says the project manager Matteo Scarpa, useful in extreme situations where, due to elevating depth, performing a maintenance intervention from the technologies installed on the ship is too risky and sometimes impossible.

The OIE equipment is now positioned at the Saipem base in Trieste, where the same company of San Donato Milanese takes care of its maintenance, so as to guarantee immediate availability for use in emergency situations. Furthermore it can be transported to the point of intervention both by sea and, after dismantling in components of air flow, by air (8 flights with Boeing 747 cargo are required).

Also at the Trieste base, Saipem manages a team of specialized personnel using the system that can operate quickly and efficiently in the event of spills.

The news of the innovative technology has not gone unnoticed even at Piazza Affari which shows a rise of 3.38% of Saipem.

Stefano Cao, CEO of the group, during the periodic conference call with analysts, said he wanted to aim, also through technological innovation, to relaunch the company.