Trigeneration: how to Generate Heat, Cold and Electricity at the Same Time

motorshow.me

Combined heat and power generation (CHP) is an ascertained energy production system. It allows to produce heat and electricity at the same time, increasing, in a remarkable way, the overall efficiency of the energy generation process (produced energy divided by primary energy). It is possible, through any kind of primary source (fossil or not), to generate steam (or superheated water) in a heat power plant (or boiler). The energy carrier (water or steam) can be used in order to produce hot water for the heating system, for high temperature industrial processes or, on the other side, it can be delivered to a turbine, which produces mechanical energy, and electricity as a consequence.

The industrial commercialization of absorption refrigerator brought with it the innovative idea: produce “cold” through heat. That could sounds as an oxymoron; but it is easy enough to explain how it works: it uses the solute dissolution heat in a solvent, which is concentrated and diluted cyclically. Therefore, when the heat has supplied in a section of the system, it is possible to take off the heat in another part of it. It has used, mainly, in case of heat recovery technologies (both industrial and tertiary ones).

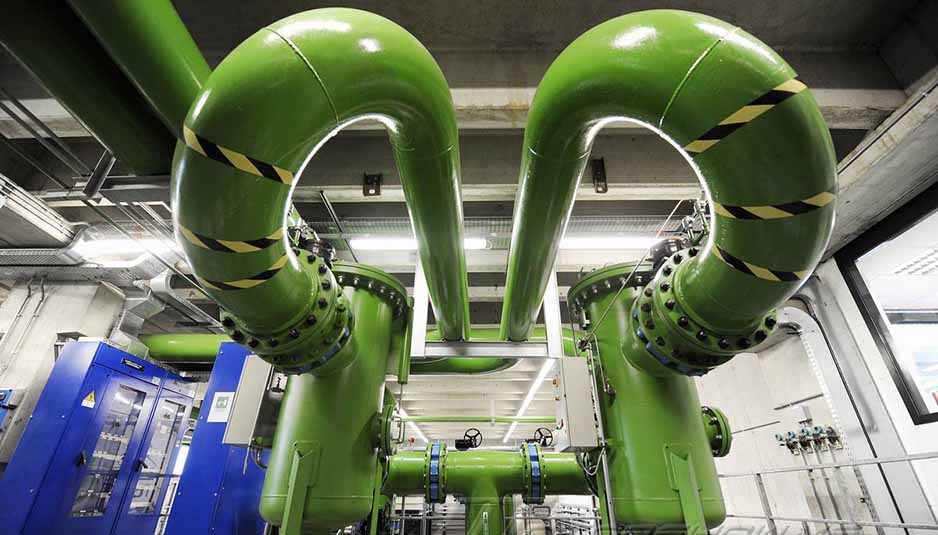

The trigeneration is the production of electricity, heat and “cold energy” with one technology. It has burned a generic fuel (usually methane) in an internal combustion engine (ICE), which produces electric energy. Its high-temperature fumes are not released in the atmosphere, but they are supplied to a heat recovery steam generator through which is possible to generate superheated water for the high-temperature users and for the absorption refrigerators (refrigerating water production). In the engine, hot water has also generated and supplied to the medium-temperature users and it is used for the “cold” production. In the figure there is a similar but simpler system.

Presuming we are a big consumers utilizing 1.000.000 Sm3 per year of natural gas in order to produce heat and electricity in cogeneration and 20.000.000 kWh per year for the extra-needed electricity (refrigerators, illumination, pumps, etc.). In case the electric energy has an important impact on our consumption, we can easily think to develop and install a trigeneration system. The latter will burn almost 5.000.000 Sm3 of methane in order to guarantee the same amount of energy used in the previous case (heat, refrigerating water and electricity). The produced electric power will be 2.500 kW, the heat power will be 2.500 kW – divided into 1.400 kWth produced in the heat recovery system and 1.100 kWth produced in the water/water heat exchanger – and the refrigerating power will be 2.000 kW – divided into 1.100 kWf and 900 kWf respectively in the superheated and heated water-working absorption refrigerators. Hypothesizing the cost of energy as 0,12 euro/kWh for electricity and 0,33 euro/Sm3 for the methane (Italy prices), we would have a 1.000.000 euros yearly saving with 3.000.000 euros initial investment cost (pay-back period almost three years): not too bad!